Our Services

- Metal Structure Fabrication

- Godowns Fabrication

- Painting

- Machine, Equipment Commissioning

- Sheeting

- Structure, Machine, Equipment Erection

- Crane, Gantry Crane Installation

- Industrial Chimneys

- Building Fabrication & Erection

- Boiler Erection, Commissioning

- Stream, Air, Oil Pipe Lining

- Conveyor, Elevator

- Silo – Erection & Fitting

- Hoppers Fabrication

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

contact@bpfabricator.com

West Bengal, India

How can we help?

Understanding the Process: I can explain the various steps involved in metal fabrication, including design, material selection, cutting, forming, and assembly.

Material Selection: I can provide information on different types of metals used in fabrication, such as steel, aluminum, and stainless steel, along with their properties and applications.

Choosing a Fabrication Service: I can guide you on what to look for when selecting a metal fabrication service, including considerations like experience, equipment, certifications, and quality control.

Project Planning: I can offer tips on planning a metal fabrication project, including cost estimation, timeline, and communication with fabricators.

Troubleshooting and Advice: If you have specific questions or issues related to metal fabrication, I can offer advice and solutions.

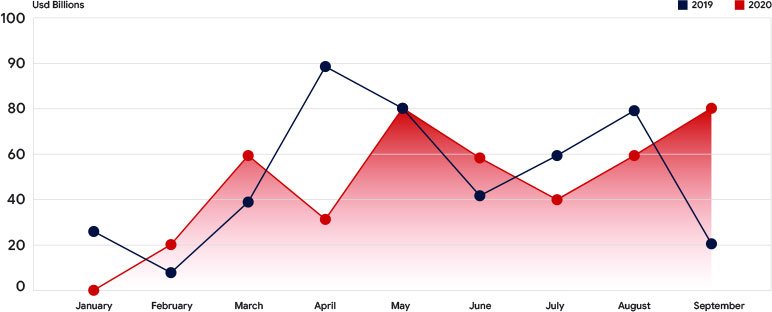

Stats & Charts

- Market Size and Growth: Global and regional market size, growth rates, and trends.

- Industry Segments: Types of metal structures fabricated (e.g., buildings, bridges, industrial machinery).

- Materials Used: Common materials in fabrication, like steel, aluminum, etc.

- Technological Advances: Innovations in fabrication techniques and machinery.

- Key Players: Leading companies in the industry.

- Employment and Labor: Employment trends, skill requirements, etc.

- Economic Impact: Contributions to the economy, investment trends, etc.

- Environmental Impact: Sustainability practices, emissions data, etc.

Our Benefits & Solutions

Metal structure fabrication involves the process of cutting, shaping, assembling, and welding metal materials to create structures or components. This can include everything from building frameworks, bridges, and towers to machinery parts, custom metalwork, and decorative pieces. The fabrication process typically involves various metals, such as steel, aluminum, and stainless steel, depending on the project requirements.

- Vestibulum consectetur lorem interdum, sollicitudin sapien ac, laoreet magna.

- Proin vel arcu pulvinar, feugiat urna in, laoreet tortor.

- Curabitur pulvinar nulla eget libero facilisis fringilla.

Custom Fabrication: Tailored solutions to meet specific project requirements, including custom designs, sizes, and specifications.

Structural Steel Fabrication: Manufacturing steel components for buildings, bridges, and infrastructure projects.

Sheet Metal Fabrication: Production of metal parts through cutting, bending, and forming thin metal sheets.

Welding and Assembly: Expert welding and assembly services to ensure structural integrity and precision.

Metal Finishing: Surface treatment processes such as painting, powder coating, and galvanizing to protect against corrosion and enhance appearance.

Prototype Development: Creating prototypes for new designs and products to ensure feasibility and functionality.

On-Site Installation: Providing installation services for fabricated metal structures, ensuring proper fit and alignment.

What is Included

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.

Steeler™ is an emerging programme built on five years of work to define and promote steel that has been produced and sourced responsibly. The Australian Steel Stewardship Forum initially developed the concept.